Corporate sustainability and social responsibility are indispensable elements of the corporate culture of Coca-Cola HBC. As a responsible economic operator, we consider it important to manage the environmental risks arising from our operations and to make a positive contribution to the protection of our environment and natural resources in many different areas.

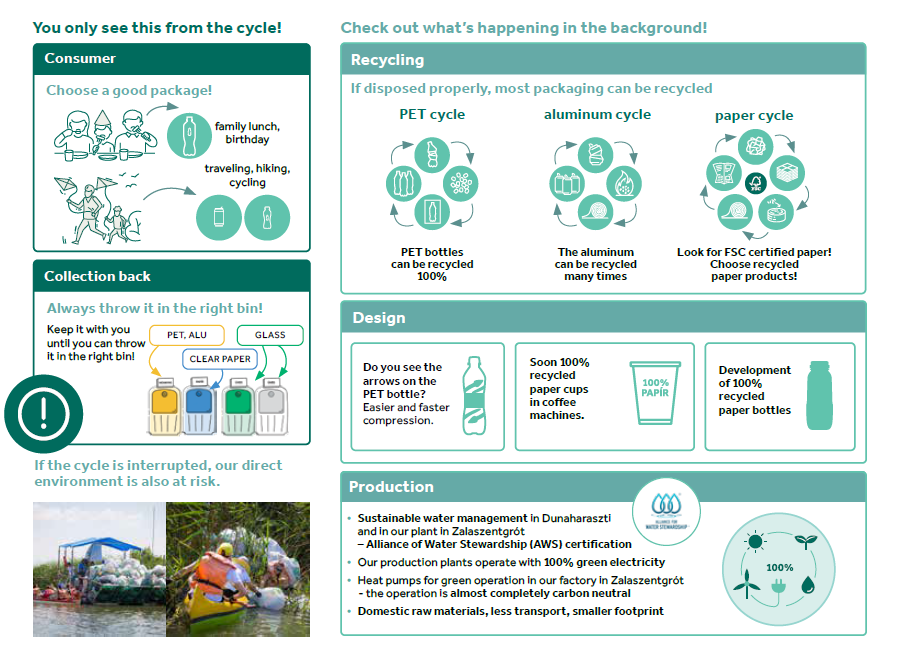

We are committed to minimizing the environmental impact of our own operations. Improving energy efficiency, reducing greenhouse gas emissions, responsible water management, and the collection and reuse of packaging waste all contribute to a more sustainable environment. In addition, we ensure that the development of responsible, sustainable operating processes goes hand in hand with raising the awareness of our employees and consumers, as we believe that wide-ranging cooperation is the foundation of our success. Our sustainability strategy and objectives are inextricably linked to our business goals, and sustainable operations are the driving force behind our growth.

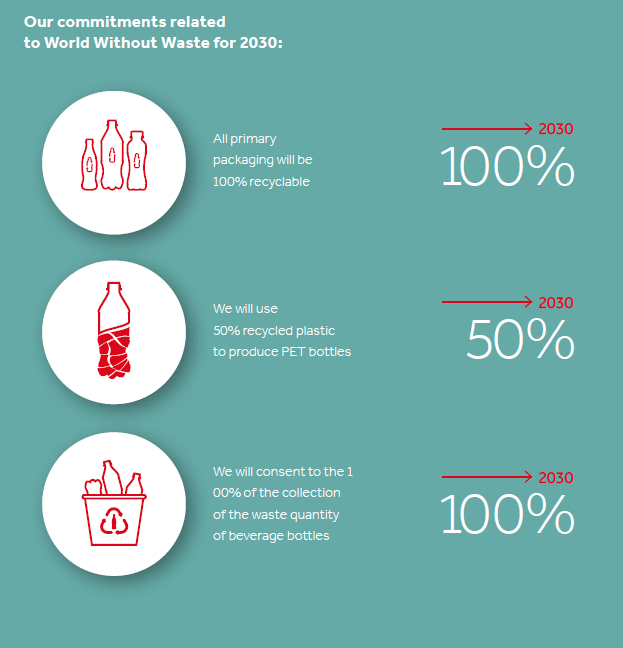

A core pillar in our sustainability strategy is the enhanced commitment toward “World Without Waste”, although our initiatives are not ended there. We are continuously working on to conduct sustainable circulation of our products’ whole lifecycle. That includes the procurement process of raw materials, design of products and packaging, production processes and also social engagement for common goals.