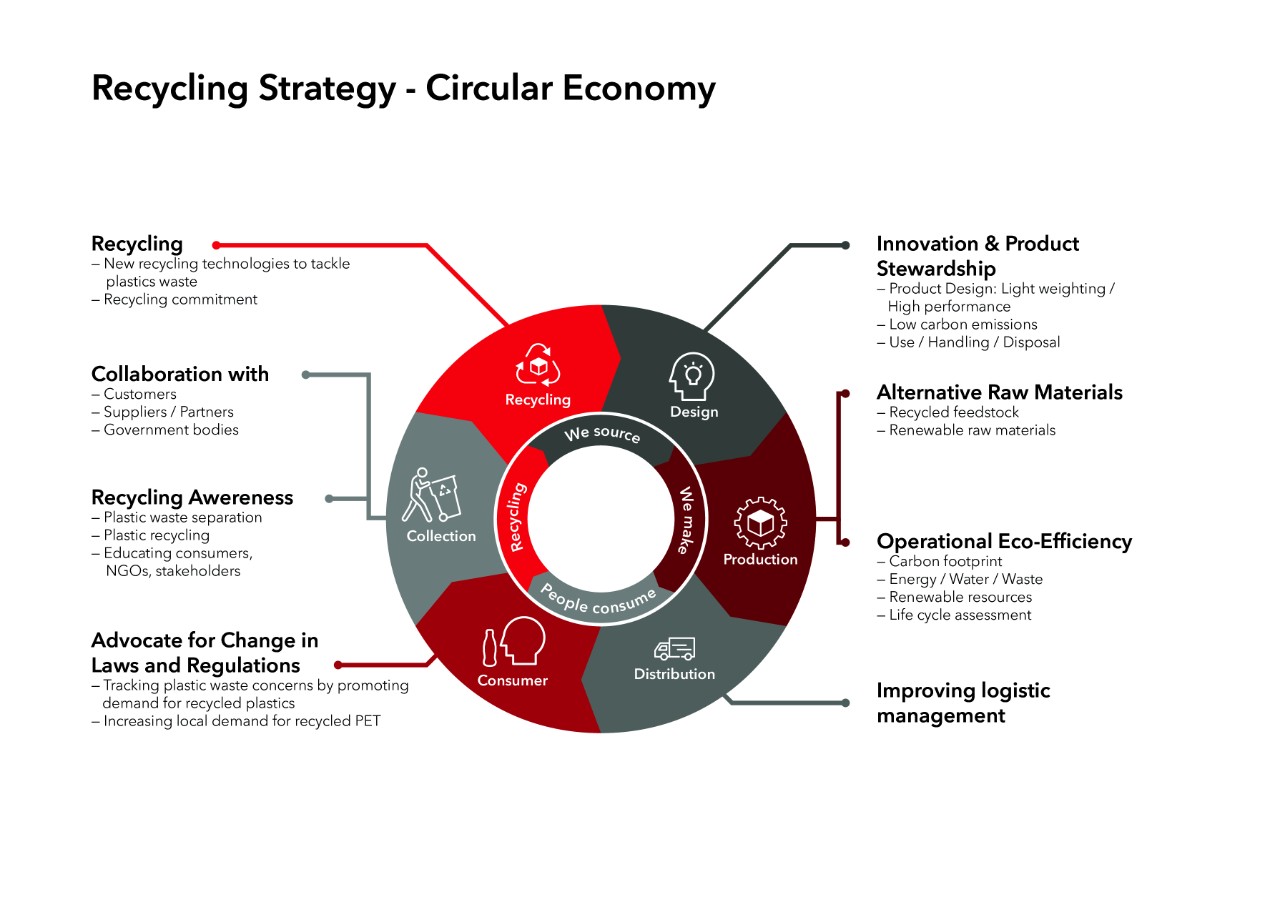

The mistreatment of plastic waste is a serious environmental issue, that is why Coca-Cola Hungary is aiming for a long-term solution by creating a circular economy. The circle of collecting and recycling packaging materials is the most efficient way to manage packaging waste, so the company optimizes its processes according to this, and strives to reduce its environmental footprint through resource efficiency and packaging innovations. With this approach, unnecessary or wasteful use of raw materials can be avoided, and materials within the circle can retain their value for a long time.

Reducing the use of strechfilm on pallets is also an important step in the pursuit of a circular economy that includes production, use, delivery, collection, and recycling as well. Thanks to the newly completed development, another 3.75 tons less waste is generated annually at Coca-Cola Hungary's depots and wholesale partners, and new foil is made from the foil waste. By closing the circle, the collection and recycling of packaging is not only a theoretical possibility, but a reality, and packaging materials are not endangering the environment this way, neither the terrestrial nor the aquatic ecosystems.

On the way for a World Without Waste

Coca-Cola Hungary has already been reducing the amount of materials used to package its products. The company uses 170 tons less aluminum per year for the packaging of canned soft drinks produced in Hungary and sold in 19 countries and uses 43 tons less plastic by reducing the amount of strechfoil needed during their delivery.

One of the goals of Coca-Cola Hungary's global World Without Waste strategy is to collect as many plastic bottles and aluminum cans as they sell by 2030, creating a sustainable cycle that spans through the entire life of a product. The PET bottles distributed by the company in Hungary are already 100 percent recyclable excluding label and cap, and thanks to these developments, the proportion of recycled plastic (rPET) in the bottle production process is constantly increasing. It averages 24 percent right now, and the company plans to rise this number to 50 percent by 2030. The amount of plastic used in domestic production has decreased by 15 percent in the last ten years, and recently, as a result of a HUF 100 million technological development, the amount of plastic used in sparkling drinks bottles has decreased by another 4 percent. This last step alone means that the company uses 600 tons less plastic per year, which equates to a total weight of 24 million PET bottles. PET bottles account for only 3% of all packaging waste in Hungary.